FILLING AND CLOSING LINE FOR HAND FILLED PRODUCTS

Adapted filling line for hand filled products in open mouth containers, like pickles of various shapes (whole, spear coin) such as dill pickles in brine, eggs in vinegar, meatballs in spaghetti sauce, stuffed peppers in oil, etc…

For these, we have developed:

- Several containers’ distributors adapted to work well with many different shapes of tubs/cups or pails with or without handle.

- A feeding conveyor with interchangeable timing screw to transfer different sizes of hand filled containers in between the cleats of the filling and closing line’s indexing conveyor (FDS1500C). This allows many employees to hand fill your container.

- Several lids’ distributors adapted to work well with many different lid shapes apply to tamper-evident or sealable containers.

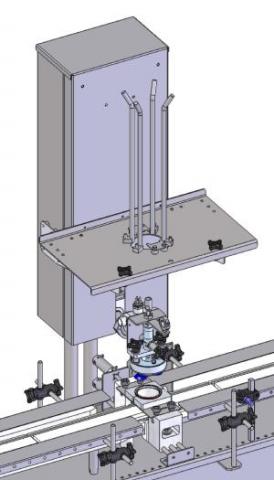

- A motorized closing head with a pneumatically activated air removing system ensuring that the lid of a tamper-evident container is pushed in while closing it to make sure it looks concave. When required, this system can expel a bit of liquid to make sure there is no more air before closing.

- A volumetric spice depositor (depositor)

- A volumetric horseradish depositor

- A time-based liquid depositor

- A liquid recuperation system under the indexing conveyor of the filling and closing line

- A special construction for corrosive environments, including all stainless-steel pneumatic cylinders and fittings, stainless-steel gearbox, etc.

Adapted Equipment

Additional Modules

For fully integrated filling lines:

- Automatic cup, tub, tray and bucket plastic film sealer: the PL500

- For the multi-lane filling lines, a lane concentrator may be required.

For small production: stand alone components can be proposed (please visit our Machine Guide), such as, for example :

- a container denester DS1500,

- a container closer FS1500,

- a lid denester and closer FDS1400,

- a filling position plus a lid denester and closer: the FDS1500,

- or an accumulation table T50.

English

English

Français

Français